Product Categories

1. Introduction to PET (Modified) Transparent Thick Plate

High mechanical strength, stiffness, and hardness. Good sliding performance and wear resistance, and good electrical insulation. Very good dimensional stability, weather resistance, and chemical resistance.

PET thick plates are processed using ordinary APET raw materials and specially modified PET raw materials. Due to its superior cost-effectiveness, it can replace PC/PMMA/GPPS panels in various occasions such as construction, decoration, and advertising. Our equipment can produce 8mm thick APET and PETG sheets.

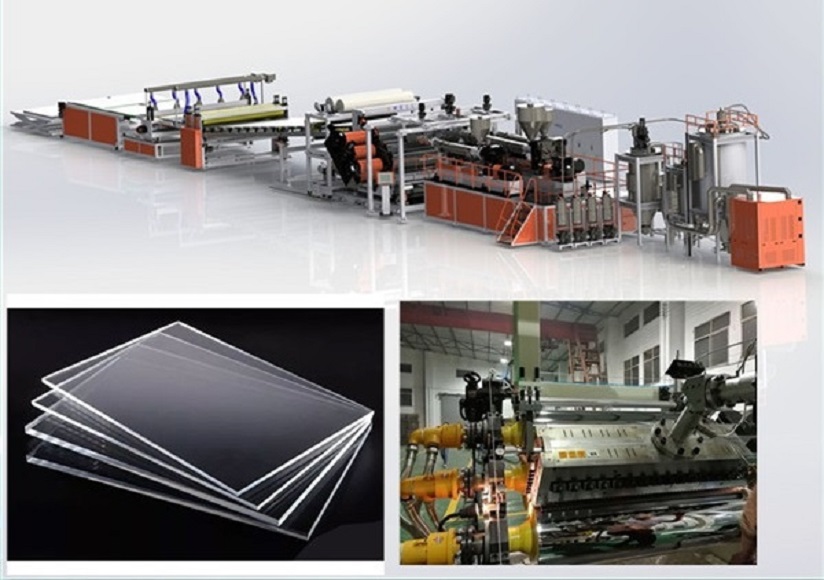

2. PET (modified) transparent thick plate production equipment

The PET thick plate extrusion production line developed by GWELL company currently lacks equipment for producing this product in the market. PET thick plates have broad prospects in China. Compared to ordinary PET plates, the thickness can only reach 1.5mm, while PET thick plates can reach 5mm.

3. Principles and characteristics of MS sheet metal production

MS is a copolymer synthesized by extracting 50% polymethyl methacrylate (PMMA) and 50% styrene (PS) as the main raw materials. It is a modified product based on acrylic products, with various parameter properties between acrylic and PS boards. Simply put, MS board is a hybrid product of PMMA and PS, which have similar characteristics. Therefore, in some fields, it can replace some acrylic boards.

In the past two years, due to the continuous increase in oil prices, acrylic materials have been on the rise. Many manufacturers have chosen cheaper MS boards to process and replace acrylic products. Products made from MS boards can replace acrylic products in some fields, but if you want high transparency products, it is recommended to choose acrylic products.

4. Introduction to Board Production Equipment

model | GWS120 | GWS150 | GWP85 |

Applicable raw materials | Modified board grade PET, MS | ||

Product width | 1000-1500mm | 1200-2100mm | 1200-2100mm |

Product thickness | 1-5mm | 1-5mm | 1-5mm |

Design extrusion yield | 300-400Kg/h | 400-500Kg/h | 500-600kg/h |