Product Categories

PETG decorative film and three-layer co extruded GAG decorative film production line

1、 Introduction to the Application and Prospects of Petg Decorative Film

Petg film has high gloss and transparency properties, and is commonly used in decoration and packaging, such as furniture panels and door panels. It enhances aesthetics by utilizing the high gloss properties of PETG decorative film. Used for high-end cosmetic packaging, utilizing good chemical resistance.

The future development prospects are broad, and due to its excellent performance and price advantages, it is gradually replacing traditional materials such as PC, PVC, PMMA, etc. in the field of application. Especially in the field of decoration, the usage is increasing. The main reason is that the PVC decorative film used previously was made from PVC, but the price of PVC has skyrocketed. In addition, people's environmental awareness has gradually strengthened, and PVC decorative films will produce unpleasant and toxic gases during the manufacturing process, causing environmental pollution. With the support of these two reasons, the Petg decorative film has been significantly applied.

2、 Introduction to Petg Decorative Film Production Equipment

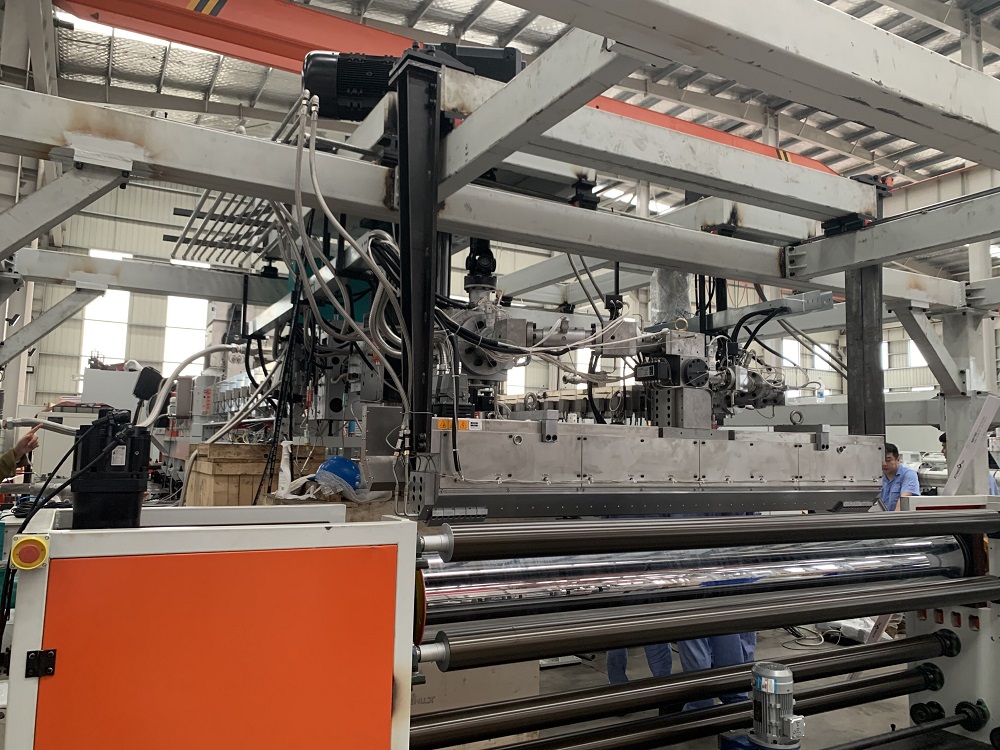

Our company's production equipment for PEG decorative film uses extrusion method to produce PEG decorative film. Our newly designed model, combined with exquisite manufacturing technology, ensures that the produced PEG decorative film has good flatness and no defects (such as crystal dots, white dots, black dots) on the surface without longitudinal and transverse lines.

Our main equipment models include two single screw extruders for co extrusion, one double screw extruder, and one single screw extruder for co extrusion. The quality of pet decorative films produced by different models may vary, mainly due to differences in film transparency. We generally recommend using a single screw extruder model for producing high gloss PEG films, and a double screw extruder model for producing color films, as this can reduce overall costs.

3、 Introduction to GAG sheets

GAG sheet is a composite sheet with many advantages and a wide range of applications. It has a three-layer sheet composite, with PETG AETG PETG in the upper, middle, and lower layers. Product features: Good transparency, transparency can reach over 90%, good texture, suitable for products that require high transparency. The film used for vacuum packaging is called hard film or film. Commonly used include PET (polyethylene terephthalate) hard sheets, PVC (polyvinyl chloride) hard sheets, and PS (polystyrene) hard sheets. PS hard sheets have low density, poor toughness, are prone to combustion, and produce styrene gas (a harmful gas) during combustion, so they are generally used to produce various industrial vacuum pallets. PVC hard sheets have moderate toughness and are not easy to burn. When burned, chlorine gas is produced, which has a certain impact on the environment. PVC is easy to heat and can be sealed by sealing machines and high-frequency machines. It is the main raw material for producing transparent vacuum products. PETG sheets have good toughness, high transparency, are easy to burn, and do not produce harmful gases during combustion. They are environmentally friendly materials, but they are expensive and suitable for high-end vacuum molded products. The advantage of GAG sheets is that they are much cheaper than PETG in price. Mainly used for decorative films and attachment films, applied in many industries such as building materials, furniture boards, packaging, pharmaceuticals, etc. Especially in the furniture industry, due to environmental protection, raw material prices, and product characteristics, PVC decorative panels are gradually replacing the original ones. The market prospects are very promising.

Production Equipment Model Table

model | GWS120+GWS65 | GWP85+GWP52 |

Product width | 1250mm | 1250mm |

Product thickness | 0.15mm -2mm | 0.15mm -2mm |

Extrusion yield | 350KG/H-450KG/H | 450KG/H-550KG/H |