Categories

1、 Introduction to TPU Car Clothing Film and Its Application Prospects

TPU car clothing film, also known as TPU paint protection film, plays a protective role in the paint surface and enhances the brightness of the paint surface. Due to the increasing demand for quality of life and the increasing number of cars, the market demand is growing. In the past, the automotive film market was always dominated by foreign countries, whether it was raw materials or production equipment. In recent years, this market has gradually attracted the attention of Chinese people, and raw materials and production equipment have gradually become domestically produced. The price of film application is also constantly decreasing. The cost of applying film to a car has decreased from 10000 to 20000 yuan to 6000 to 8000 yuan. With the rise of the car clothing film industry, breaking away from foreign monopoly control, the price will continue to decline and return to a reasonable level.

2、 Introduction to TPU Car Clothing Film Production Process and Equipment

TPU film is usually produced by casting method. Special treatment is required before TPU particles are put into the extruder. TPU particles are plasticized in the extruder and extruded through a mold, using a three roll cooling system for cooling and shaping. Due to the high elasticity of the TPU base film and its tendency to get caught in air, it is not possible to roll larger sized finished products. Therefore, the double-sided PET release film method is used in the production process to roll larger rolls. The product specifications range from 1300mm to 1600mm in width and 0.08-0.3mm in thickness. It can be produced using one or more screw extruders, with a production capacity of 150-400KG/H. The product structure can be designed in single-layer, multi-layer A/B/A or A/B modes.

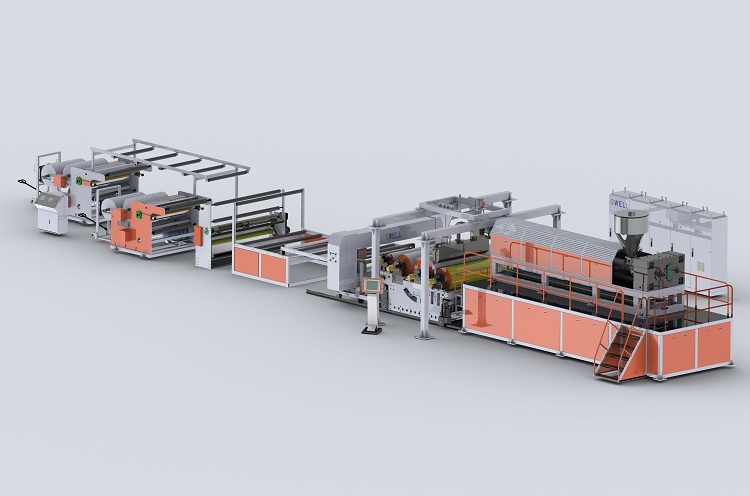

Gwell's mechanical equipment consists of 1. raw material processing system 2. extruder 3. screen changer and metering pump 4. mold 5. three roll cooling molding machine 6. first unwinding device 7. second unwinding device 8. thickness gauge 9. cooling system 10. waste edge winding device 11. temperature control system 12. winding machine, etc.

Host model | Single screw GWS105 | Single screw GWS105/GWS65 |

Product structure | monolayer | Double or triple layered |

Product thickness | 0.1mm - 0.3mm | 0.1mm - 0.3mm |

Product width | 1520mm | 1520mm |

Product output | 150KG/H - 200KG/H | 200KG/H - 250KG/H |