Product Categories

Introduction to PC optical film extrusion production line products

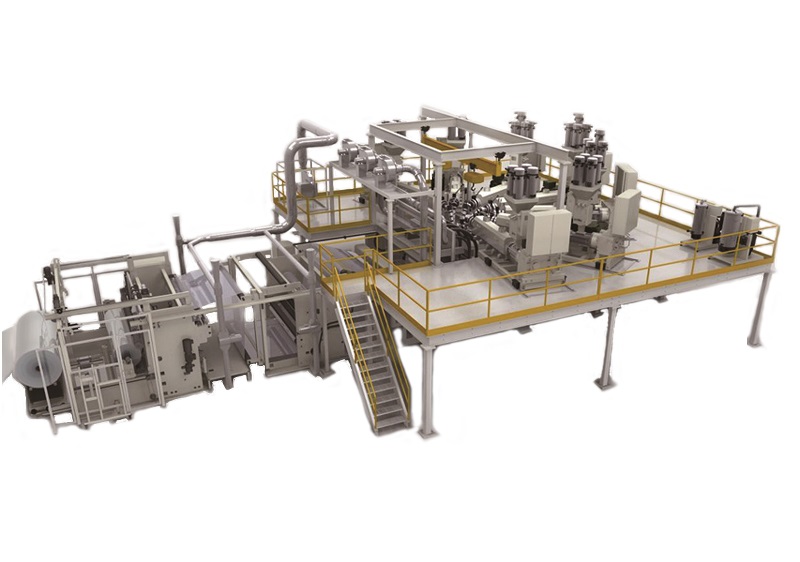

The optical grade PC film production equipment PC film production line is mainly composed of single screw extruder, screen changer, metering pump, mold, thickness gauge, winding, electrical control and other components. At present, PC optical grade thin films are mainly used in the product field, so in terms of molds and thickness gauges, our company is mainly equipped with sincere automatic molds and well-known brand thickness gauges. To meet the needs of the market, Suzhou Jinwei Machinery Co., Ltd. has provided customers with PC optical grade thin film production lines through process technology and equipment. The specialized screw and precise metering pump system and mold designed based on the rheological properties of the raw materials ensure the uniformity and stability of the melt and the excellent optical properties of the sheet; The precise calendering system provides assurance for the mechanical and physical properties of the sheet.

2. Introduction to PC optical film

PC film performance: It has good heat resistance, stable mechanical properties, dimensional stability, electrical properties, and flame retardancy, and can be used for a long time at -60~120 ℃; No obvious melting point, in a molten state at 220-230 ℃; Due to the high rigidity of molecular chains, the viscosity of resin melt is high. Has excellent physical and mechanical properties; Excellent impact resistance, high tensile strength, bending strength, and compressive strength; Low creep resistance and stable size.

3. Application of PC optical film

The PC film application market is extensive and currently has a wide range of applications in various industries. Jinwei Company has launched a PC optical grade film extrusion production line to address this situation. The production line has a high degree of automation and accuracy, and the main components and electrical components are made of foreign brands, ensuring the stable performance and long-term use of the equipment.

model | Gws65 | Gws90 |

Product width (mm) | 600-800 | 800-1200mm |

Product thickness (mm) | 0.05-0.5mm | 0.05-0.5mm |

Extrusion yield (kg/h) | 100-200kg/h | 200-300kg/h |