Product Categories

1、 Introduction to PVA film

Biodegradable PVA film. Water soluble PVA film is a new type of plastic product that has emerged internationally. It utilizes the film-forming properties, water and biological degradation characteristics of PVA, and can be completely degraded into CO2 and H2O. It is truly a green, high-tech, and environmentally friendly packaging material. In Europe, America, and Japan, water-soluble PVA films have been widely used for packaging various products. The development of water-soluble PVA films in China is still in its early stages, and industrial research and development have only truly begun in the past five years. They are mainly used in embroidery and water transfer printing (color printing of glass, ceramics, electrical casings, etc.), with an annual usage of about 10000 tons of PVA in this field.

China is a major consumer of plastics. Among the current annual consumption of nearly ten million tons of various plastic films, if PVA films replace a 5% share, the annual demand will reach hundreds of thousands of tons. With China gradually aligning with international standards and increasing environmental requirements for packaging, the promotion and development of water-soluble PVA packaging films provide strong support, and their potential market is also quite large.

In terms of food packaging, due to the excellent gas barrier and oil resistance of PVA water-soluble film, these characteristics can extend the shelf life of packaged food and maintain its composition and odor well.

In terms of textile packaging, PVA water-soluble film packaging is used to package textiles. Compared with general packaging materials, it has advantages such as no static electricity, transparency, glossiness, and better texture than other packaging materials, making the packaging objects present a more distinct and clean appearance, and improving the value of the product. Due to the high air barrier properties of PVA water-soluble film, it can block the nitrogen in the air and prevent textile yellowing when used in textile packaging.

In terms of chemical packaging, discarded packaging materials for pesticides and fertilizers have become a major public hazard, and PVA water-soluble film packaging bags have been widely used in packaging for pesticides and fertilizers due to their good water solubility and mechanical strength.

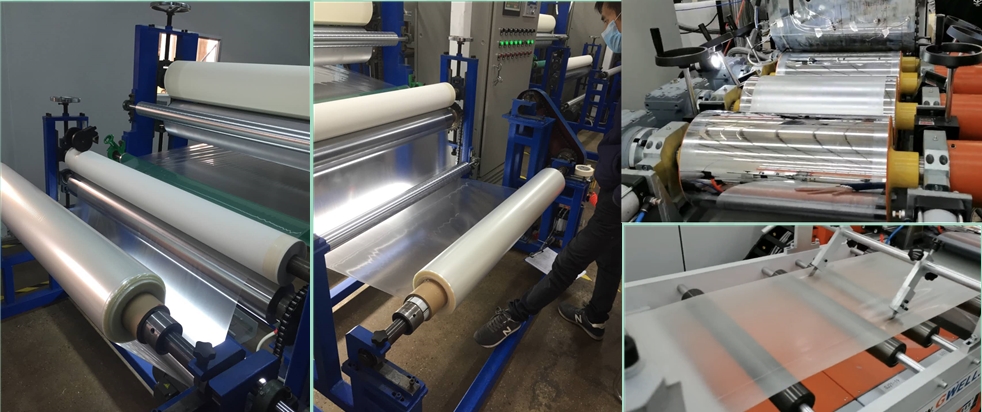

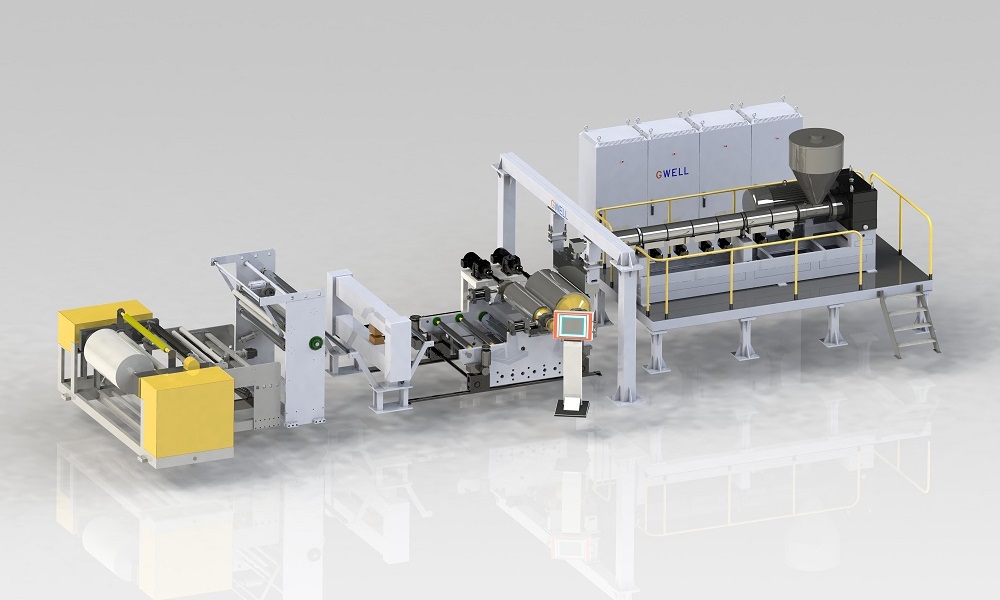

2、 Introduction to PVA water-soluble film production line

The environmentally friendly and energy-saving PVA water-soluble film production equipment is a device that our company has independently developed and innovated for many years, producing biodegradable and environmentally friendly films. It breaks through the old manufacturing process of low production, unstable quality, high energy consumption, and high cost in traditional steel strip mold making; Our new equipment technology adopts a mixing tank, a casting and film forming mechanism, a drying and forming mechanism, and a traction and winding mechanism; Its characteristics are: on the side of the drying and forming mechanism close to the casting and film forming mechanism, there is a set of adjacent supporting rods and specially designed molds with their upper edges rotating forward (referring to the direction of slurry flow), an external heating system, and a specific and reasonable production process. The PLC program is automatically controlled to complete the process. The equipment has the characteristics of high automation, easy operation, fast line speed, uniform film thickness, high precision, good transparency and glossiness, and stable quality.

| Host model | Product width(mm) | ProductsThickness(mm) | Production(kg/h) |

| GWS90 | 800-1300 | 0.03-0.08 | 100-150kg/h |

| GWS120 | 1000-1800 | 0.03-0.08 | 250-350kg/h |