Product Categories

Product characteristics of PET unidirectional stretching film production equipment

According to the special performance requirements of the film in the field of use, this film not only has excellent physical and mechanical properties of polyester film, but also has excellent optical properties, good transparency, low haze, high glossiness, good thermal stability, low thermal shrinkage rate, smooth and smooth surface, good peeling performance, and light aging resistance. In addition, OPET thin film also has high uniaxial tensile strength and unidirectional orientation, suitable for use in special fields. Polyester film shrink film is a new type of packaging material, which is easy to recycle, odorless, and has good mechanical properties, especially in compliance with environmental protection requirements.

Main uses of the product

1. Tin composite film: After being combined with tin, it can be used for packaging various foods, beverages, and other products;

2. Electronic component packaging: It can be made into anti-static packaging bags to shield sensitive electronic components, circuit boards, communication equipment electronic products, etc;

3. In terms of pharmaceutical packaging: mainly used for pharmaceutical tablet packaging;

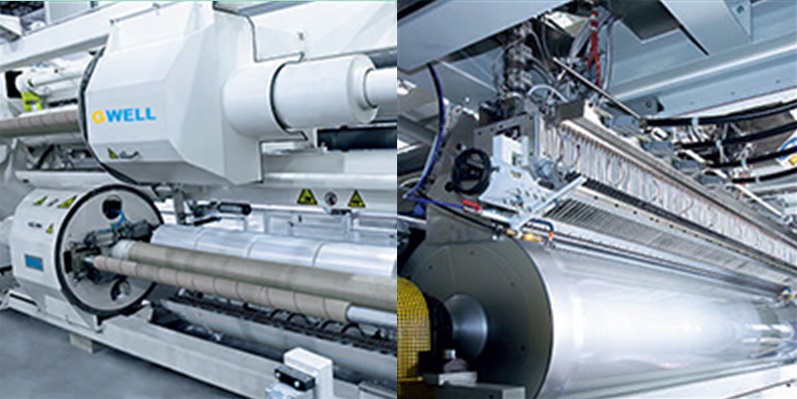

Characteristics of the production line

1. Adopting a single screw or twin screw extruder structure, it can produce single-layer, double-layer, or three-layer co extruded cast films;

2. Based on the special characteristics of PET materials or the characteristics of modified PET materials, a specially designed extrusion processing technology is adopted. Through dehumidification and drying, automatic metering and feeding, extruder plasticization, T-shaped casting die head, forming and shaping device, automatic post measurement system, preheating and stretching shaping device, surface treatment device, trimming and edge material treatment device, and fully automatic winding device, high-quality or films with special orientation properties are processed, Can be used in various fields.

Production Line Technical Configuration Table

| model | GWS90 | GWS105 | GWS120 |

| Width (mm) | 800-1000 | 1000-1500 | 1000-1500 |

| Thickness (mm) | 0.02-0.1 | 0.02-0.1 | 0.02-0.1 |

| Maximum yield (kg/h) | 100kg/h | 130kg/h | 230kg/h |