Categories

Introduction to PP/PE hollow grid board

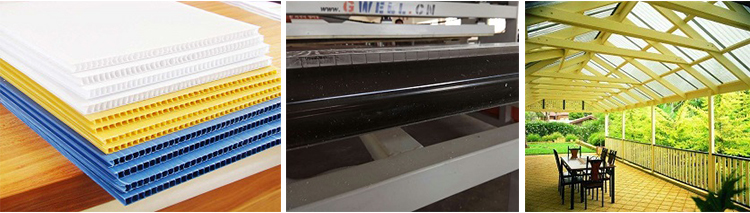

PP, PE hollow board (also called hollow grid board, Wantong board, corrugated board, double wall board) is called pp plate sheet in English. It is a new material with light weight (hollow structure), non-toxic, pollution-free, waterproof, shockproof, anti-aging, corrosion resistant, and rich colors. Compared to cardboard structured products, hollow boards have advantages such as moisture resistance and corrosion resistance. PP grid board application: PP hollow grid board can be processed into turnover boxes, packaging boxes, etc. due to its lightweight, high strength, moisture-proof, good environmental performance, and secondary processing performance.

2. Introduction to PP/PE hollow grid board production equipment

GWELL's PP/PE hollow grid board production equipment relies on more than ten years of manufacturing experience. Our machines produce PP/PE boards with smooth and flat surfaces, which can be changed in color according to requirements. It is more convenient to apply UV printing patterns on the surface of the boards. The length can be set according to the needs; The width range is 800mm-2100mm; The thickness range is 2mm to 15mm. The raw materials used have a wide range of shapes, and can be used in both particle and flake forms.

3. Parameters of the hollow grid board production line (please consult sales engineers for details):

| model | Single screw GWS120 | Single screw GWS120/GWS65 | Flat double GWP75 |

| Product structure | Single layer A | A; A/B/A | Single layer A |

| Applicable raw materials | PP, PE | PC | PC, PP, PE |

| Product width | 1220mm -2100mm | 1300mm -2100mm | 1220mm -2100mm |

| Product thickness | 2mm -8mm (can manufacture S-shaped products) | 4mm-40mm | 2mm -40mm |

| Extrusion yield | 180KG/H -350KG/H (specifications affect production) | 250KG/H -450KG/H (specifications affect production) | 200KG/H -450KG/H (specifications affect production) |