Product Categories

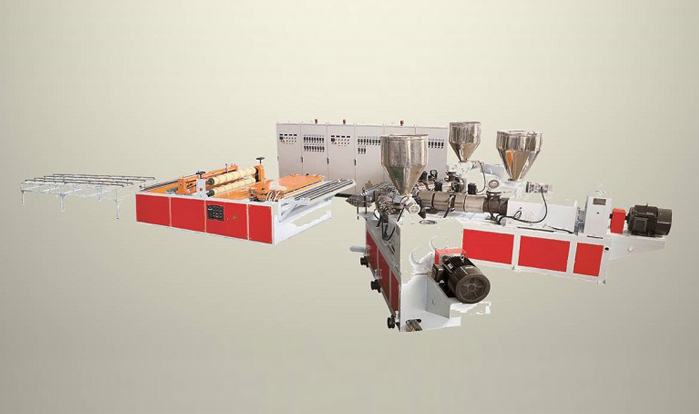

Features of production line equipment for PC, PP, PE, PVC, ASA corrugated board, corrugated board, glazed tile, and hollow tile:

The clothes rack type flat machine head is equipped with a pneumatic opening and closing molding die, a flexible and safe lifting mechanism, making the molding more reliable and the thickness adjustment extremely convenient;

Adopting rubber traction rollers that are consistent with the waveform, the traction is particularly stable, and the roller spacing adjustment device is convenient and fast, with on-site processing capabilities for various situations;

The meticulously designed cutting method and oblique edge automatic cutting make the incision more neat, and can automatically cut according to the required length, highlighting the people-oriented design concept.

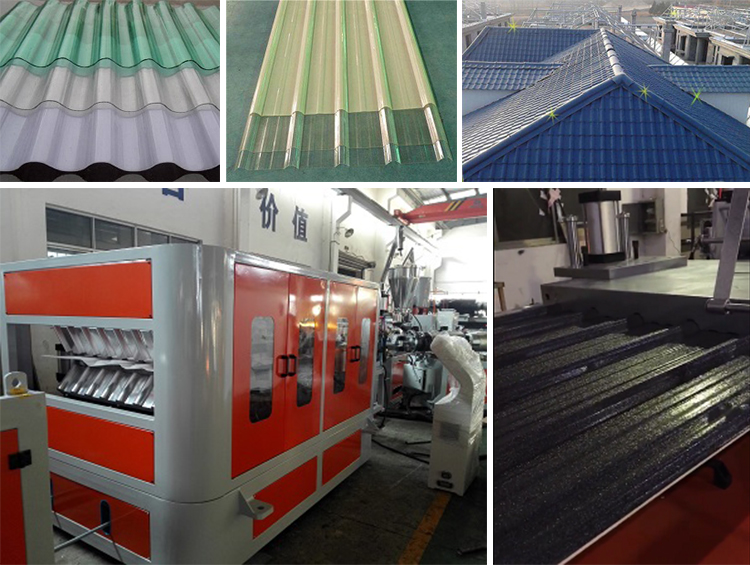

The characteristics and applications of PVC wave tiles, corrugated boards, glazed tiles, and hollow composite tiles:

Excellent fire resistance, belonging to flame retardant materials, without self ignition, resistant to chemical corrosion, acid and alkali, fast heat dissipation, excellent lighting performance, and long service life;

Using a special technical formula, ASA can be co extruded, resistant to outdoor atmospheric exposure, good insulation performance, and can provide a more comfortable environment than metal tiles in hot summer;

Widely applicable, it is very suitable for factories, warehouses, car sheds, agricultural markets, hoardings, walls, temporary shops, insulation sheds, etc

PC Wave Board, Corrugated Board, Sunlight Tile:

It is mainly made of polycarbonate (PC) as the main raw material, and added with UV resistant agents and other chemical raw materials, using advanced technology today. The product has excellent stability, is not prone to yellowing or deterioration, and has a high ability to absorb strong ultraviolet radiation within the ultraviolet spectrum range (290-400nm). And it has been proven through experiments that up to 99.9% of ultraviolet rays can be effectively isolated. Widely used in roof panels for building covers, patios, car sheds, balconies, canopies, screens, pavilions, swimming pools, etc. Wave panels can also be used as roof materials for industrial and agricultural buildings.

PP, PE wave board:

At present, there are mainly dozens of pattern shapes such as straight ripple, water ripple, surfing pattern, golden nail pattern, textile pattern, snowflake pattern, etc. The surface effects include nearly thirty effects such as pure white board, gold and silver paste, pearl board, star board, cracked paint board, imitation stone, etc. It is a new type of fashionable art interior decoration board.

Parameters of production lines for corrugated and corrugated boards (please consult sales engineers for details):

| model | Cone double GWC65/132-GWC80/156-GWC65/132 | Single screw GWS120-GWS65 | Single screw GWS120 |

| raw material | PVC, ASA | PC, ASA | PP, PE |

| Product structure | A/B/C; A/B/A; A/B; A | A/B/A; A/B; A | A |

| Product waveform | Waves, corrugated, fish scales, hollow corrugated, etc | Waves, corrugated, fish scales, hollow corrugated, etc | Waves, corrugated, fish scales, hollow corrugated, etc |

| Product thickness | 0.8mm -3mm | 0.6mm -1.5mm | 0.5mm -3mm |

| Product width | 1200mm | 1400mm | 1050mm |

| yield | 300KG/H -350KG/H | 350KG/H -400KG/H | 300KG/H -400KG/H |