Categories

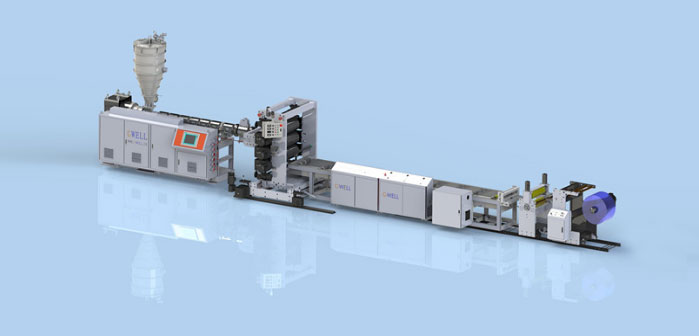

The Gwell ultra transparent PVC soft door curtain production line uses a single screw extruder to produce PVC pellets. The special screw structure, combined with the Jinweier vacuum hopper, enables the product to achieve a transparent effect, and the product will not harden in the severe cold of minus 30 degrees Celsius; The design of the auxiliary equipment adheres to the principle of one machine for multiple uses, and can produce three different patterns of PVC door curtains without stopping production without any changes to the equipment. Gwell Machinery's soft PVC ultra transparent production line technology belongs to Jinwell and is a world leading technology.

Features of the extrusion production line for ultra transparent PVC soft door curtains:

*The screw is designed with special mixing function and high plasticizing ability.

*The hanger type die head adopts a special double flow control design, making the thickness adjustment of the board more precise.

*Temperature control ± 1C can accurately control the plasticization process and the thickness and flatness of the product.

*The three roller calender adopts a horizontal, vertical, or 45 degree tilt type and can be freely lifted and lowered.

*The thickness control of the sheet metal adopts screw adjustment and pressure wheel bi-directional adjustment to control the thickness of the sheet metal

Gwell PVC Ultra Transparent Soft Door Curtain/Crystal Panel Features:

*Smooth surface, no cracks, no bubbles, uniform color, heat resistance, cold resistance, aging resistance, heavy pressure resistance, strong acid and alkali resistance, good light transmittance, and long service life. To a certain extent, it can replace glass, but its excellent performance is incomparable to glass. Especially the impact resistance and tensile strength of soft glass not only ensure its long service life, but more importantly, it does not cause harm to the human body. Its warm in winter and cool in summer, as well as its soft texture, make desktop office workers particularly comfortable to work on.

*Anti light, non deformation, non shattering, non hardening, high elasticity.

*Soft texture and easy to write

*Heat resistant to 100 ℃, cold resistant to -30 ℃, resistant to strong acids and alkalis, resistant to heavy pressure, helps improve the efficiency of desktop work, reduces cleaning costs for restaurants, and adds elegance and aesthetics to the restaurant

*One step extrusion molding, the product is not layered and remains soft in low temperature environments

Basic parameters of PVC soft door curtain extrusion production line (please consult sales engineer for details)

| Host type | Single screw exhaust extruder (with Jinweier patented vacuum system) |

| Three roll forming machine | Three function vertical calender |

| Product width | 150mm -450mm |

| Product thickness | 0.4mm -4mm |

| Product yield | 150KG/H -400KG/H (production varies depending on the model) |