Product Categories

The plastic transparent sheet production line of Gwell Machinery Co., Ltd. fully absorbs and digests the world's advanced extrusion technology from Europe and the United States. The main components are selected from the world's products (such as screws, machine barrels, rollers, etc.). The energy consumption, intelligence, automation indicators, safety standards, and process standards of the complete set of equipment have all reached high standards. This series of products has multiple invention and utility model patents to replace imported equipment and has a cost-effective advantage. The high-end transparent board products produced are widely used in various industries such as optics, home appliances, construction engineering, decoration, furniture, advertising, handicrafts, and other industries, as well as civil use. The quality has reached the performance of world products, and we have a team of matching expert process engineers to help users debug and produce high-quality products.

PMMA light guide plate: Guide the light flux of LED point light sources to be evenly distributed throughout the entire surface, and use the reflection mechanism to use the light flux more efficiently and control the light distribution.

PC, GPPS diffusion plate: disperses the light flux, evenly distributes the light (some composite diffusion plates not only homogenize the light, but also control the exit angle), and supports the backlight architecture to protect the optical materials below from damage

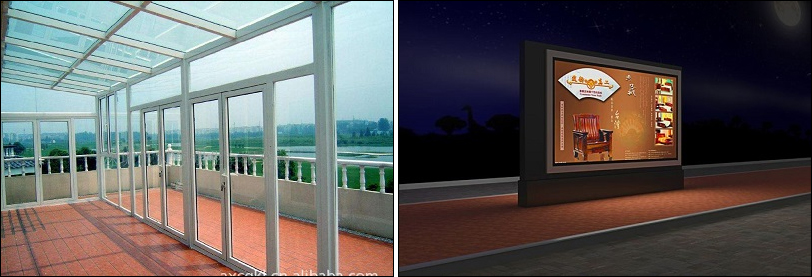

PMMA (acrylic), GPPS, MS board: widely used in instruments, instrument parts, lighting fixtures, decoration, building materials, aircraft, automotive parts, medical equipment, process products, electrical insulation materials, specimens, signs, and various light industry, cultural and educational, daily necessities, etc.

Parameters of plastic transparent sheet machine set (please consult sales engineer for details)

| model | Single screw GWS120 | Single screw GWS120/GWS65 | Single screw GWS90/ 150/90 | Flat twin screw GWS75 |

| Using raw materials | PC, PMMA, GPPS, PET, MS | PC, PMMA, GPPS, PET, MS | PC, PMMA, GPPS, PET, MS | APET, PETG modification |

| Product structure | Single layer A | A; A/B; A/B/A | A; A/B; A/B/C | Single layer A |

| Product width | 600mm -1500mm | 600mm -2100mm | 1220mm -5000mm | 600mm -1500mm |

| Product thickness | 0.8mm -15mm | 0.8mm -15mm | 0.8mm -15mm | 0.8mm -15mm |

| Extrusion yield | 300KG/H -350KG/H | 350KG/H -450KG/H | 500KG/H -750KG/H | 350KG/H -450KG/H |