Product Categories

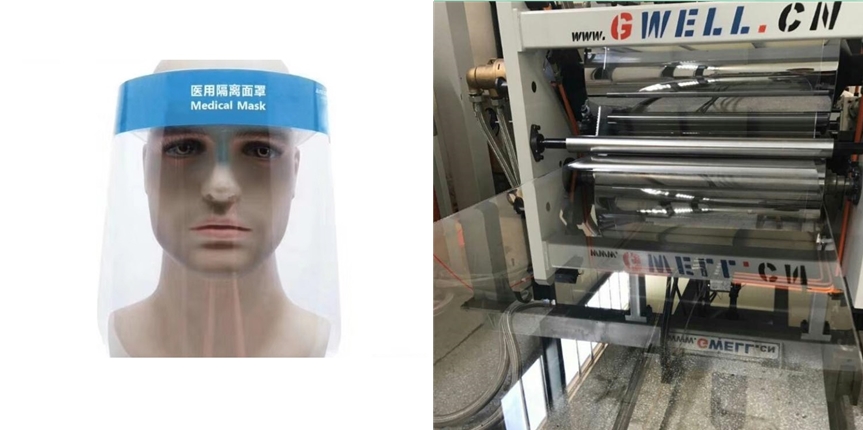

The screw of PET optical sheet production equipment adopts a special mixing function and a high plasticizing ability design, reducing the generation of crystal points. The hanger type die head adopts a special throttling design with coarse and fine adjustments, making the thickness adjustment of the sheet more precise. The PET film production line equipment manufactured by Jinwell has reached high equipment standards in terms of energy consumption, intelligence, automation indicators, safety standards, and process standards. This device has multiple invention and utility model patents, which is a choice to replace imported first-class equipment, but it has a cost-effectiveness advantage. The temperature control of the three roller calender is ± 1 ℃, which can accurately control the plasticization process and the thickness, flatness, and brightness of the sheet metal. Different types of three roller calendering machines are used for different materials of boards to improve the production process.

Basic parameters of PET optical sheet production line (please consult sales engineer for details)

| Model | 90 single screw extruder | 120 single screw extruder | 150 single screw extruder |

| Product width | 600mm -1000mm | 800mm -1200mm | 1000mm --1500mm |

| Product thickness | 0.15mm -2mm | 0.15mm -2mm | 0.15mm -2mm |

| Extrusion yield | 200KG/H -300KG/H | 300KG/H -400KG/H | 500KG/H-600KG/H |