Categories

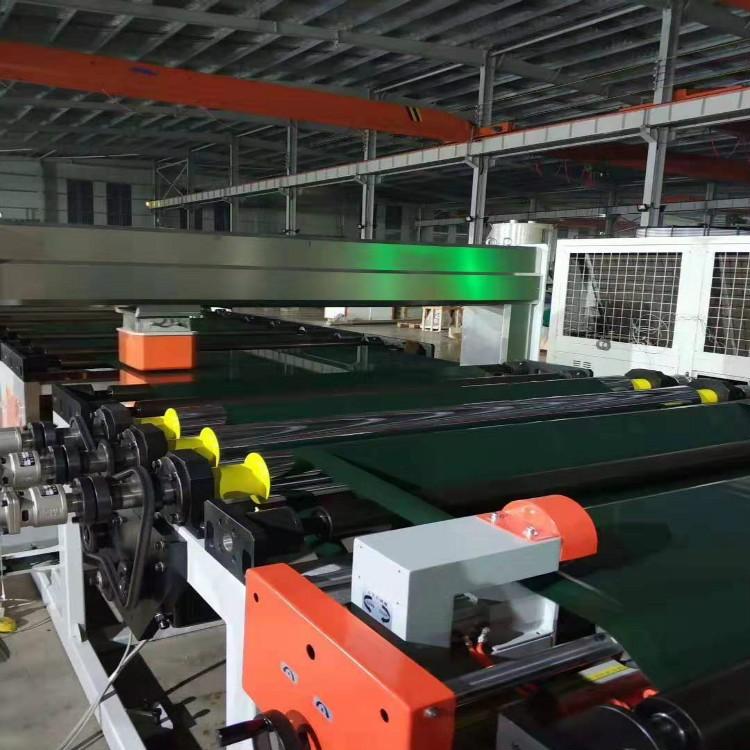

Introduction to ASA Casting Film Production Line

ASA is a copolymer of styrene, acrylonitrile, and acrylic rubber. Technically speaking, ASA not only maintains the main characteristics of ABS, but also combines the advantages of acrylic weather resistance to extend the application of the product to outdoor use. ASA film products are made from high content of ASA adhesive powder raw materials, and have completely passed the 12000 hour weather resistance test. The color retention performance is many times higher than that of co extruded materials currently available in the market. The uniformity of ASA film is higher than that of co extruded material, with no color difference in thin spots and no waste of scraps. Therefore, the current ASA casting film production line has become a development trend.

The characteristics of the ASA casting film production line equipment produced by our company:

1. The entire set of equipment adopts PLC, closed control, one click acceleration, and convenient operation.

2. The special screw design of the extruder ensures plastic melting, uniform color, and high extrusion volume

3. The fully automatic mold, combined with a thickness gauge, can more effectively fine tune the melt thickness deviation on the transverse width of the mold head, ensuring a thickness uniformity of ± 1 thread.

4. The casting roller adopts an internal channel integrated machining method to ensure temperature control of plus or minus 1 degree, roll surface control accuracy of plus or minus 1 thread, and ensure more accurate casting film thickness.

5. Using a tension sensor and control system to ensure tension control of plus or minus 1 Newton.

6. A complete set of servo motors, combined with servo controllers, ensures more accurate equipment operation.

7. The fully automatic cutting and coiling machine has two functions: contact coiling and gap coiling. The tension control of the coiling belt taper has an adjustment range of 5-200N/M

model | GWS90-1500 |

Applicable raw materials | ASA |

Product width | 1400mm |

Product thickness | 0.05-0.2mm |

Extruder specifications | GWS90/33 |

Extrusion yield | 150-180kg/h |