Product Categories

LVT (Luxury Vinyl Tile) stone plastic flooring is another name for PVC sheet flooring.

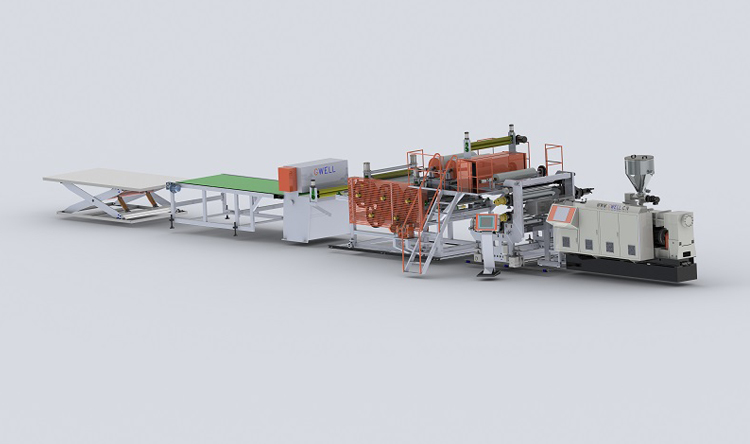

In 2013, Gwell successfully developed an LVT floor extrusion and lamination production line, and achieved one-time lamination of WPC floor veneer materials, improving production line efficiency and ensuring stable quality. Compared to other countries in Europe and America, it has a high sales volume. LVT flooring is widely used in various fields of home decoration and commerce due to its rich variety of patterns and colors.

LVT floor extrusion production process: PVC, calcium powder, plasticizers and other raw materials are fully mixed by a high-speed mixing unit and then sent to a conical double extruder by a screw conveyor. The bottom material is extruded with a T-shaped mold and the wear-resistant layer and printing layer are segmented and bonded to obtain products of specified thickness. The extrusion bonding production process can replace traditional complex processes such as rolling and lamination, with simple operation, low investment cost, reduced labor intensity of workers, and a clean workshop environment, The entire line adopts optical sensors for detection and alarm, with a high degree of automation.

LVT flooring production line parameters (please consult sales engineers for details)

| model | Cone double GWC80/156 | Cone double GWC92/188 | Pingshuang GWP75/36 |

| Product width | 1000mm | 1000mm | 1000mm |

| Product thickness | 1.5mm -2mm | 2mm -5mm | 1.5mm -5mm |

| yield | 350KG/H -400KG/H | 550KG/H -650KG/H | 400KG/H -500KG/H |