Product Categories

SPC flooring one-step extrusion production line

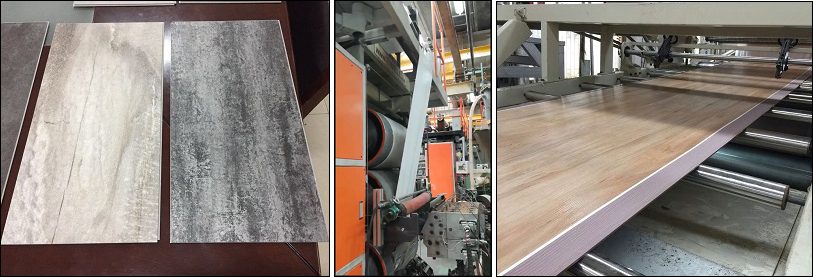

The English name for SPC flooring is Stone Plastic ComPosite, which is also the abbreviation for hard PVC flooring sheets

SPC flooring is a product produced by a conical double extruder to produce flooring substrates. After passing through a three roll or four roll rolling machine, PVC color film, PVC wear-resistant layer, and PVC substrate are pressed and bonded together in one go. The process is simple, easy to operate, and the bonding is completed by heat without the need for glue. SPC stone plastic flooring is a new type of environmentally friendly flooring developed based on high technology. It has the characteristics of zero formaldehyde, anti mold, moisture-proof, fireproof, insect proof, and easy installation. SPC flooring materials use environmentally friendly formulas and do not contain harmful substances such as heavy metals, phthalates, formaldehyde, etc. They meet national and industry standards and are widely popular in developed countries in Europe, America, and the Asia Pacific market. With its excellent stability and durability, stone plastic flooring not only solves the problem of solid wood flooring being deformed and moldy due to moisture, but also solves the problem of formaldehyde in other decoration materials. It has a wide range of colors and patterns to choose from, suitable for indoor home decoration, hotels, hospitals, shopping malls and other public places.

Kinwell technology can meet the needs of SPC floor synchronous flower production. After tempering treatment, the shrinkage rate is ≤ 1 ‰, and without tempering treatment, the shrinkage rate is ≤ 2.5 ‰ (shrinkage test standard: 80 ℃, 6-hour standard)

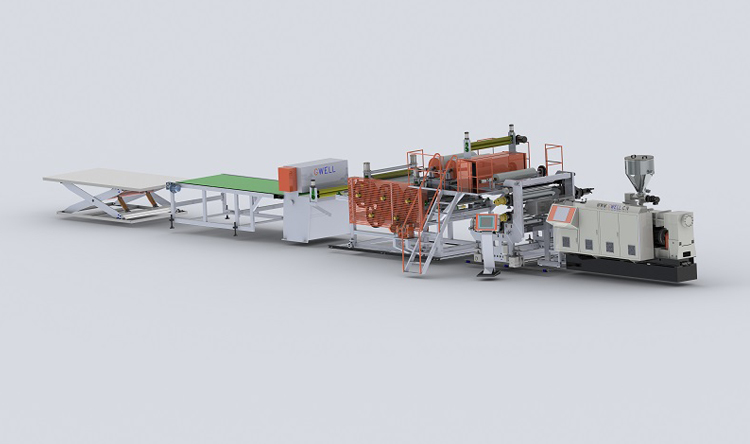

SPC flooring one-step extrusion production line

The English name for SPC flooring is Stone Plastic ComPosite, which is also the abbreviation for hard PVC flooring sheets

SPC flooring is a product produced by a conical double extruder to produce flooring substrates. After passing through a three roll or four roll rolling machine, PVC color film, PVC wear-resistant layer, and PVC substrate are pressed and bonded together in one go. The process is simple, easy to operate, and the bonding is completed by heat without the need for glue. SPC stone plastic flooring is a new type of environmentally friendly flooring developed based on high technology. It has the characteristics of zero formaldehyde, anti mold, moisture-proof, fireproof, insect proof, and easy installation. SPC flooring materials use environmentally friendly formulas and do not contain harmful substances such as heavy metals, phthalates, formaldehyde, etc. They meet national and industry standards and are widely popular in developed countries in Europe, America, and the Asia Pacific market. With its excellent stability and durability, stone plastic flooring not only solves the problem of solid wood flooring being deformed and moldy due to moisture, but also solves the problem of formaldehyde in other decoration materials. It has a wide range of colors and patterns to choose from, suitable for indoor home decoration, hotels, hospitals, shopping malls and other public places.

Kinwell technology can meet the needs of SPC floor synchronous flower production. After tempering treatment, the shrinkage rate is ≤ 1 ‰, and without tempering treatment, the shrinkage rate is ≤ 2.5 ‰ (shrinkage test standard: 80 ℃, 6-hour standard)

SPC floor composite production line parameters (please consult sales engineers for details)

| Model | Cone double GWC80/156 | Cone double GWC92/188 | Cone double GWC92/188+cone double GWC80/156 |

| Product Structure | Single layer | Single layer | Triple A/B/A |

| Product width | 1000mm | 1000mm | 1000mm |

| Product thickness | 2mm-5mm | 2mm-5mm | 2mm-5mm |

| Output | 350KG/H-400KG/H | 600KG/H-750KG/H | 850KG/H-1100KG/H |