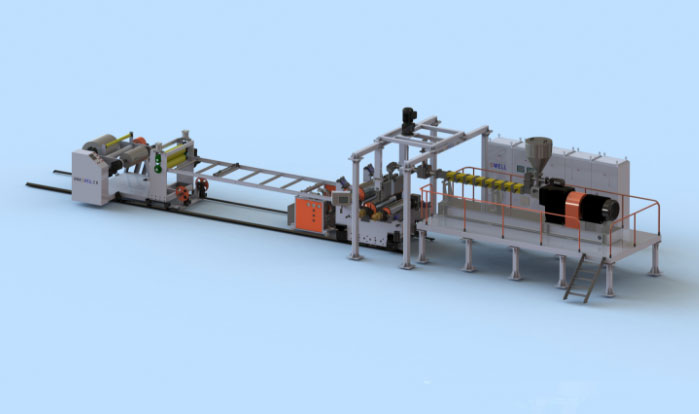

PLA sheet extrusion production line

Polylactic acid, also known as polylactide, belongs to the polyester family. Poly (lactic acid) is a polymer obtained by polymerization of lactic acid as the main raw material, commonly known as corn plastic. It has abundant sources and can be regenerated. It is mainly made from L-lactic acid produced from corn and cassava as raw materials, and is a new type of biodegradable polyester material through processes such as condensation, cracking, purification, and polymerization. The production process of polylactic acid is pollution-free, and the product can be biodegradable, achieving circulation in nature. Therefore, it is a suitable green polymer material and also a high-tech and environmentally friendly product encouraged by the country. It is widely used in electronic product casings, automotive parts, medical equipment, clothing fibers, agricultural films, food packaging, tableware and other fields.

Gwell Machinery PLA sheet extrusion production line is suitable for the production of PLA (polylactic acid) and modified PLA. PLA (polylactic acid) originates from plant resources and can be directly used for extrusion molding. Due to its biodegradability, compostability, and recyclability, PLA and soluble PLA are widely used in various food packaging and hardware packaging. Equipped with a melt metering pump for quantitative extrusion, speed and pressure closed-loop control, the film thickness is uniform. The rollers are independently driven, and the linear speed of each roller is synchronously controlled. The whole machine adopts PLC control, with automation of actual parameter setting, data calculation and feedback, alarm and other functions.

Multiple extruders can be used for co extrusion technology to produce multi-layer co extruded composite PLA or starch sheets, which are widely used in hot forming, printing, hardware packaging, etc.

*Equipped with precision distributors, evenly layered, adjustable proportions for each layer, and digital control accuracy.

*The inclined horizontal tablet pressing structure makes operation and maintenance more convenient.

*The roller has independent power and synchronous closed-loop control of linear speed and extruder speed.

*The whole machine adopts PLC control, achieving automatic control of parameter setting, data calculation and feedback, alarm and other functions.

*The electrical control system and operating procedures are independently written by Gwell

Basic parameters of PLA sheet production line (please consult sales engineer for details)

| model | PLA sheet single screw extrusion production line | PLA sheet parallel twin screw exhaust extrusion production line |

| raw material | PLA or starch | |

| Product structure | Can produce single-layer, double-layer, three-layer, and multi-layer PLA or starch degradable sheets | |

| Product width | 600mm -1220mm | |

| Product thickness | 0.17mm -2mm | |

| Extrusion yield | 200KG/H -800KG/H | |