Categories

The common PP/PS sheet extrusion production lines are single machine single-layer sheet production lines and double machine co extrusion three-layer sheet production lines. There are also multi machine co extrusion multi-layer production lines, which can process 7-9 layers of composite sheet production lines, such as high barrier EVOH multi-layer co extrusion sheets. This model can process polyolefin materials such as PP, PS, PE, etc.

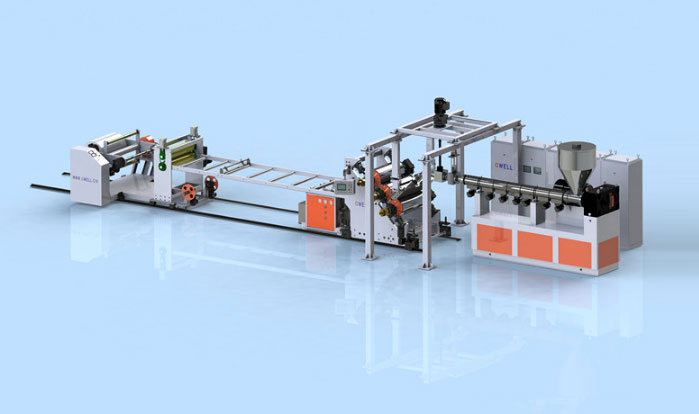

Gwell PP/PS sheet production line:

We use multiple extruder co extrusion technology to produce multi-layer co extruded composite PP and PS sheets, such as multi-layer structures such as ABA, ABCBA, ABCDCBA, etc., which are widely used in hot forming, printing, hardware packaging, electronic pallets, flocking, food, clothing, tools, toys, stationery sheets, decorative sheets, etc.

*Equipped with precision distributors, evenly layered, adjustable proportions for each layer, and digital precise control.

*The inclined horizontal tablet pressing structure makes operation and maintenance more convenient.

*The roller has independent power and synchronous closed-loop control of linear speed and extruder speed.

*The whole machine adopts PLC control, achieving automatic control of parameter setting, data calculation and feedback, alarm and other functions.

*Kinwell independently wrote an electronic control operating system

The main uses of PP/PS sheets are:

*PP/PS blister sheets

*PP/PS single-layer sheet, PP/PS co extruded dual color sheet, PP double-sided high transparency sheet, and other sheets used in the vacuum packaging industry.

*PP stationery piece

*PP transparent sheets, frosted sheets (coarse sand, fine sand), two-color sheets, and other sheets used in the stationery packaging industry.

*PP micro foam sheet has advantages. PP foam sheet with a density greater than 0.45g/m3 has good bending resilience and is not easily deformed, and has broad application prospects in the field of folders; PP foam sheets with a density of 0.6g/m3 have good mechanical properties and have a very broad prospect in the field of automotive interior decoration; Can be processed into carpet support materials, shading boards, soundproofing boards, luggage racks, interior decorations, covers, boxes, etc; PP foam sheets with a density of 0.3g/m3 have good flexibility and resilience, making them suitable for packaging, partition boards, and other fields.

Basic parameters of PP/PS sheet extrusion production line (please consult sales engineer for details)

| Model classification | PP/PS single machine extrusion production line | PP/PS dual machine co extrusion sheet production line | The PP/PS multi machine co extrusion composite sheet production line is capable of | |

| Can produce single-layer sheet materials | Can produce double-layer or three-layer structural sheet materials on the production line | Can produce multi-layer structural sheets, mostly consisting of five, seven, or nine layers | ||

| Host type | The host can be either a single screw extruder or a parallel twin screw extruder | |||

| Wide width | 600mm -1220mm | |||

| thickness | 0.15mm -3mm | |||

| yield | 200KG/H -1000KG/H (there may be production differences among different models) | |||