Categories

Since entering winter, the temperature has dropped rapidly. Jinweier Machinery kindly reminds friends: to prevent the sudden drop in temperature from affecting your company's normal production, please check the equipment in your workshop in a timely manner, and maintain the equipment as soon as possible after shutdown and power outage, to avoid short circuits caused by prolonged shutdown, moisture in electrical components, and freezing of water pumps and vacuum pumps due to low temperature, which will affect normal production next year. The specific measures are as follows:

1. Please check the electrical components of each device for aging, looseness, poor contact, etc. Before starting up next time, please use a multimeter to measure whether the three-phase voltage is normal. Only when the voltage is normal, there is no leakage or short circuit, can power be turned on. If the machine is shut down for a long time, record the parameters on the computer screen to prevent parameter loss.

2. Please check the moving parts of each device for sufficient lubrication, especially the frequently running parts such as screws, rollers, bearings, and guide pillars, to prevent the moving parts from getting stuck due to low temperature, which may affect normal production. At the same time, the gearbox oil of the equipment should be changed every 4000-5000 hours of operation, at least once a year.

If the temperature is low and the oil pump pressure is high, you can preheat the gearbox oil first, and then start the oil pump after the temperature rises. The oil filter element of the hydraulic system needs to be replaced every six months, and the pressure of the energy storage tank needs to be checked regularly (7MPa)

4. Please check the tension of various transmission components such as belts and chains. Low temperatures may cause damage to the original tension balance, with minor damage to the belts and chains. The rubber pads at the coupling should be checked for coaxiality and wear every three months

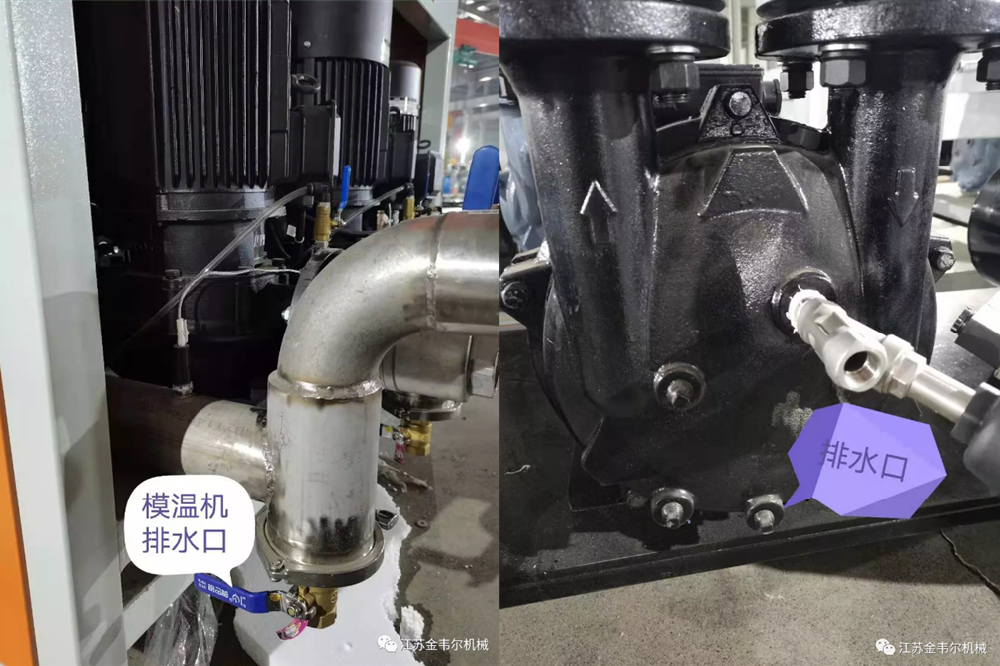

5. When the indoor temperature is below zero and the machine is shut down, it is necessary to drain the water from the water pump, water ring pump, condenser and other water supply equipment to prevent rusting of the pump blades and freezing (cracking) of the equipment.