Product Categories

Composite bipolar plates are composed of two or more materials, which have the advantages of high conductivity of graphite materials and high toughness of polymer materials. It is currently a hot research and development topic. The commonly used bipolar plates for commercial flow battery stacks are carbon composite materials, usually made of conductive fillers (graphite, carbon black, carbon fiber, carbon nanotubes, etc.) Thermoplastic resins (such as polyethylene, polypropylene, polyvinylidene fluoride, etc.) also have good corrosion resistance and liquid resistance.

Graphite is a commonly used conductive filler for composite bipolar plates. When the graphite content is high, the conductivity of the bipolar plate increases, but the airtightness and mechanical strength decrease. However, when the resin content is high, the airtightness and mechanical strength of the board increase, but the conductivity decreases. Therefore, it is necessary to precisely control the content of graphite and resin. In addition, the type, size, and shape of graphite fillers also have a significant impact on the electrical and mechanical properties of bipolar plates.

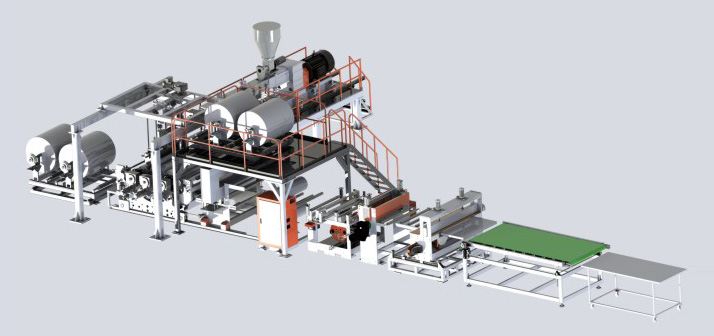

The composite graphite bipolar plate continuous extrusion equipment produced by Gwell Machinery is independently developed by our company, using extrusion technology and online continuous composite technology. The products produced have advantages such as high flatness, good surface quality, and good thickness uniformity. Compared with traditional molding technology, they have high continuity, high production capacity, and low energy efficiency.