Product Categories

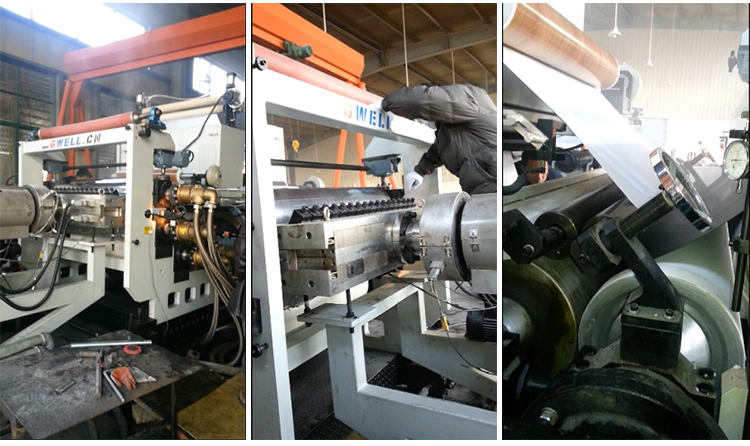

PVC commercial foam roll flooring extrusion line

PVC commercial foam roll flooring is a new type of lightweight floor decoration material that is relatively trusted in China, also known as "lightweight flooring material". Using polyvinyl chloride and its copolymer resin as the main raw materials, adding fillers, plasticizers, stabilizers, foaming agents, coloring agents and other auxiliary materials, PVC foam substrate is made through an extruder. The wear-resistant layer, printing layer, and substrate are pressed and bonded in one go.

PVC commercial foam roll flooring is a popular product that is popular both domestically and internationally. It entered the Chinese market in the early 1980s and has been widely recognized in large and medium-sized cities in China. It is widely used in various places such as homes, hospitals, schools, office buildings, factories, public places, supermarkets, commercial areas, etc.

Advantages of commercial flooring: green and environmentally friendly, super wear-resistant, high elasticity and super impact resistance, super anti slip, fire and flame retardant, antibacterial, waterproof, moisture-proof, acid and alkali corrosion resistance, attractive and noise proof, small seams and seamless welding, fast installation and construction, a wide variety of colors, and convenient maintenance. It can be welded according to general welding procedures and can also be bonded with other PVC materials.

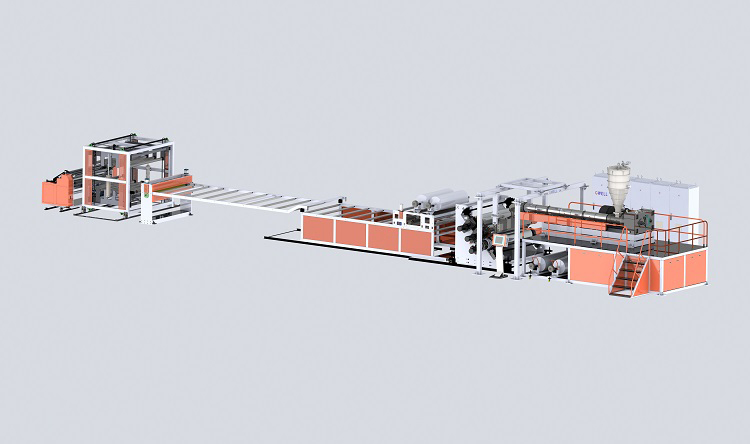

PVC foam roll flooring production line parameters (please consult sales engineers for details)

| model | Single screw GWS120/34 | Cone double GWC80/156 | Pingshuang GWP85/36 | Flat double GWP95/40 |

| Product width | 1500mm-2000mm | 1500mm-2000mm | 2000mm-3000mm | 2000mm-3000mm |

| Product thickness | 2mm to 4mm | 2mm to 4mm | 2mm to 4mm | 2mm to 4mm |

| Product output | 300KG/H-350KG/H | 300KG/H-350KG/H | 400KG/H-500KG/H | 550KG/H-600KG/H |